2018, Global Environment-friendly of Plastic Material Year

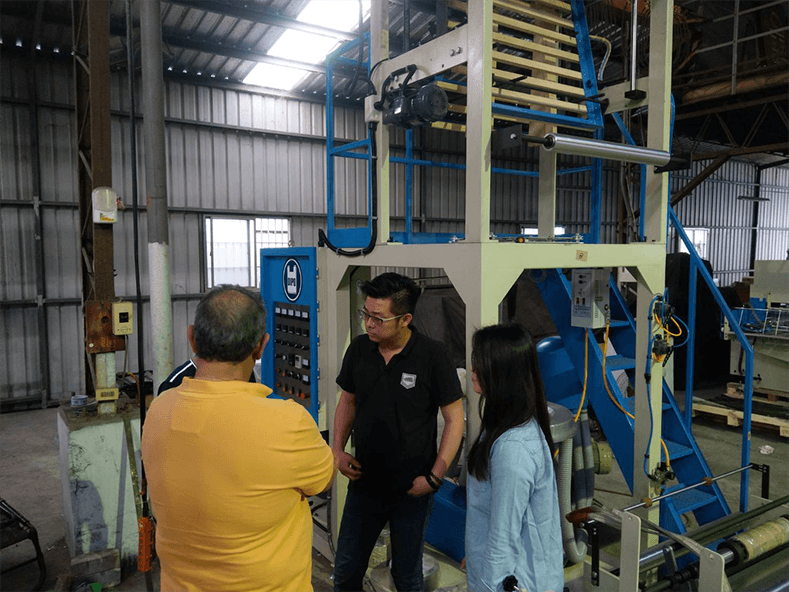

Customers in North America came to Taiwan for the PLA experience of DIPO Plastic Machinery.

In 2005, the industry of plastic raw material in Taiwan began to study the PLA of environmentally friendly materials. From the government plastics unit to the plastic academic community and the plastic bag factory, we are fully committed to the development of environment-friendly of PLA.

DIPO Plastic Machinery also fully cooperates with about 150 plastic units, and strives for environmental protection.

Plastic environment-friendly PLA characteristics, designed by the screw of the bag blowing machine, the screw ratio of 32:1 to 28:1 to 40:1 is related to the mixing ratio, dissolution, PLA temperature, extrusion amount, and then to the die test. LDPE and HDPE affect the thickness control of plastic environment-friendly material PLA. After the extrusion, the molding yield, the cooling time ratio, and the preservation of the plastic film roll will affect the quality of the plastic film printing due to the temperature, humidity, sunlight, air, water content, PLA material transportation, etc. of the four seasons. It has also taken a long time to differ from inks in the way of gravure presses and letterpress, in order to develop many ink formulations with plastic printing ink suppliers.

The plastic environment-friendly material PLA has come to the plastic film sealing process after completing the process of producing plastic film for the film blowing machine and the printing machine. This is the final process of the plastic bag product. Plastic environment-friendly material PLA is chemically changed when the plastic film is wound into the material, the roller pressure, the material of feeding roller, and the plastic environmental protection material, which affects the plastic environmental protection material PLA plastic bag. The first step of production speed. The chemical changes produced by the printing sensor sense the plastic environment-friendly material PLA printing.

After the contact with the air and the reflection of the plastic film deformed by the air, the German professional printing sensor company also joined the team to study the plastic environment-friendly material PLA. In the discharge section of the plastic environment-friendly PLA film roll, the chemical change of the air and the change of the weight ratio of the plastic environmental protection material PLA affect the curve ratio and the steel setting of the servo driver, which makes the Yaskawa Japan servo motor and the servo driver factory also joined the research team of plastic environment-friendly PLA.

Finally, the sealing and bag-cutting process of the plastic environment-friendly material PLA, in response to the characteristics of the environment-friendly plastic material PLA, is to study and try various raw materials and production methods from Germany, Japan, Europe, and Taiwan in the material of the plastic bag sealing knife (casting , forging, etc.). Sealing line angle, width, heating tube heating and heating area, etc., will affect the sealing and cutting of PLA plastic environmental protection material.

In 2010, Taiwan's plastic environmental protection material PLA has matured. It is used in Taiwan coffee shops and super market. It uses plastic environmentally friendly PLA plastic bags to replace the original plastic bags produced by HDPE and LDPE plastic materials.

In 2016-2018, factories in Taiwan producing plastic environment-friendly PLA raw materials and PLA environment-friendly plastic bags are all made of plastic-friendly materials PLA special bag making machines designed by DIPO Plastic Machinery.

DIPO Plastic Machinery Factory spares no effort to contribute to the global environmental protection. We also fully shares the experience of producing plastic environment-friendly PLA environmental protection bags for customers from North America and around the world.